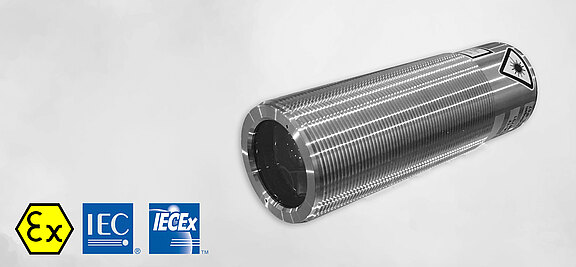

Sensor type

- ATEX and IECEx certificated

- For use in Ex Zones (0), 1, 2

- Measurement range analog output: 0.05m to 30m

- Measurement range digital output: 0.05m to 30m

- High measurement accuracy

- Analog output signal 4mA to 20mA and serial data interface RS-485

- Easy alignment through visible red light laser

- Stainless steel 1.4404 housing

- ATEX and IECEx certificated

- For use in Ex Zones (0), 1, 2

- Measurement range analog output: 0.05m to 30m

- Measurement range digital output: 0.05m to 30m

- High measurement accuracy

- Analog output signal 4mA to 20mA and serial data interface RS-485

- Easy alignment through visible red light laser

- Stainless steel 1.4404 housing

- With built-in heating element to prevent lens fogging

- ATEX and IECEx certificated

- For use in Ex Zones (0), 1, 2, (20), 21, 22

- Measurement range analog output: 0.05m to 30m

- Measurement range digital output: 0.05m to 30m

- High measurement accuracy

- Analog output signal 4mA to 20mA and serial data interface RS-485

- Easy alignment through visible red light laser

- Stainless steel 1.4404 housing

Highlights

- Time-of-flight based distance measurement (laser distance measurement or laser time-of-flight measurement or laser path measurement)

- Can be used directly in Ex zones 1, 2, 21, 22, may radiate into Ex zones 0 and 20

- Distance meter with large measuring range from 0.05m to 30m distance

- Displacement meter with 1mm resolution via RS-485

- Length measurement also via configurable analog interface 4-20mA

- complies with laser class 2 with red laser (635nm)

- in explosion-proof M42 housing made of stainless steel

- Attention further development!

- Simple and customer-friendly parameterization options

- Lens heating to prevent condensation on the optics

- Intermittent and continuous operation possible

Applications

- Positioning of system parts

- Collision protection

- Fill level measurements, e.g. silo fill level, biogas fill level, adhesive fill level, waste water fill level

- Distance measurements, length and height measurements, level measurements in biogas plants, coating plants, flexographic printing machines, pharmaceutical machines and much more.

Applications can be found wherever precise measurements are required in potentially explosive areas, even over long distances, e.g. in the automotive industry, pharmaceutical industry, chemical industry, biogas and methane gas industry, waste water and sewage treatment technology, etc.

Laser distance sensors in hazardous areas (laser distance measurement)

In explosion-proof areas, also known as hazardous areas, laser distance sensors are often used to perform various tasks. Here are some applications for laser distance sensors in hazardous areas:

1. level measurement: laser distance sensors are used to precisely measure the level in tanks, silos or containers. They can measure the distance between the sensor and the liquid or bulk material and thus determine the exact fill level. This is important to avoid overfilling and to ensure safety in potentially explosive areas.

2. collision detection: Laser distance sensors can be used to prevent collisions between moving parts or vehicles. They measure the distance to other objects or obstacles and can send an alarm signal or stop operation if the distance becomes too small. This is particularly important in areas with moving machinery or vehicles to prevent accidents and possible explosions.

3. access control: Laser distance sensors can be used to monitor entrances or entry areas. They measure the distance to people or objects and can detect whether someone is entering or is in a certain area. This enables effective access control and prevents unauthorized entry into hazardous areas.

4. early fire detection: Laser distance sensors can be used in combination with other sensors to detect fires at an early stage. They can measure the distance to potential fire sources and trigger an alarm if there is a sudden increase in distance, which can indicate a change in the environment. This allows fire protection measures to be initiated in good time.

5. inspection and maintenance: Laser distance sensors are also used for inspection and maintenance tasks in hazardous areas. For example, they can be used to measure distances, gaps or cracks to detect possible structural problems. This enables regular monitoring and maintenance to ensure the safety and integrity of installations.

Rely on 50 years of experience, proven and innovative products and solutions specifically for hazardous areas from Tippkemper-Matrix!

Technical inquiries

For technical inquiries, please do not hesitate to contact us:

Phone:

+49 2206 9566-0

Fax:

+49 2206 9566-19

info@tippkemper-matrix.de

![[Translate to Englisch:] Datenblatt herunterladen [Translate to Englisch:] rodukte Anwendungen Service & Downloads Unternehmen Kontakt & Support Laserdistanzsensoren der Produktfamilie LDx](/fileadmin/_processed_/a/1/csm_LDx_2792af6bb4.jpg)